Bitumen is a black or dark-colored (solid, semi-solid, viscous), amorphous, cementitious material that can be found in different forms, such us rock asphalt, natural bitumen, tar and bitumen derived from oil, which is referred to as petroleum bitumen.

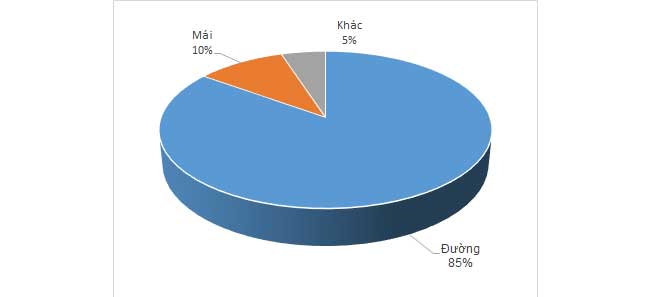

Currently most of the roads globally are paved with bitumen. Today the world’s demand for bitumen accounts for more than 100 million tons per year which is approximately 700 million barrels of bitumen consumed annually.

Petroleum bitumen is typically referred to as bitumen or asphalt. In Europe for instance bitumen means the liquid binder. In North America, on the other hand the liquid binder is referred to as asphalt, or asphalt cement.

Origin

In general the term “bituminous materials” is used to denote substances in which bitumen is present or from which it can be derived. Bituminous substances comprise of primarily bitumens and tars.

Bitumen occurs in nature in several forms: hard one - easily crumbled bitumen in rock asphalt and softer, more viscous material which is present in tar sands and asphalt 'lakes'. Another way in which bitumen can be obtained is through petroleum processing in this manner the bitumen is essentially the residue yielded through a distillation process of petroleum. Although bitumen can be found in natural form, the world currently relies for all purposes on petroleum. The material has been produced in this way for over a hundred years.

Tars on the other hand do occur in nature. Tars derive as condensates from the processing of coal (at very high temperatures), petroleum, oil-shale, wood or other organic materials. Pitch is produced when a tar is partially distilled so that the volatile components have evaporated.

Often coal tar is confused with bitumen however they are two entirely chemically different products and should not be mistaken. For the distinction drawn between petroleum bitumen and coal tar see the distinction table below:

| Bitumen | Coal Tar | |

|---|---|---|

| Origin | Naturally ocurring. | Derives from coal. |

| Production | Petroleum processing from crude oil (petroleum), the process does not involve cracking or thermal conversion. Comes from animal matter. | Through a process of carbonization of coal pyrolisis of coal at a high temperature. It is essentially a by-product of the production of coke from coal. Comes from plants matter. |

| Appareance | Black, sticky, viscose, thermoplastic. | Thick, black, sticky liquid. |

| Application | Construction. Currently, approximately 80% of bitumen demand is for road construction. | Construction, medicine coal tar is also added to the dye treatments that are administered to the fabrics. Coal tar was also used for road construction and water proofing until it was replaced by bitumen after the Second World War. |

| Toxicity | Not carcinogenic. | Carcinogenic. |

UNDERSTANDING BITUMEN FEEDSTOCK & TECHNOLOGY

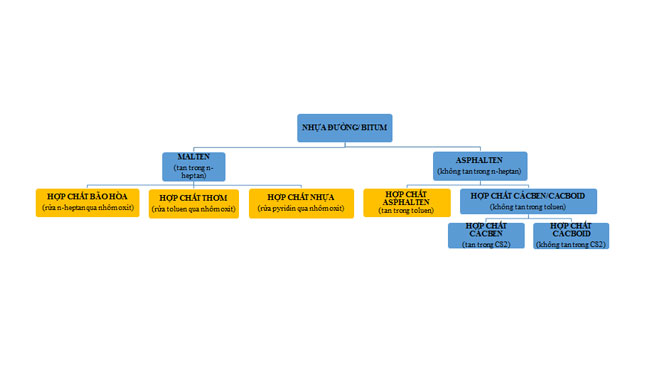

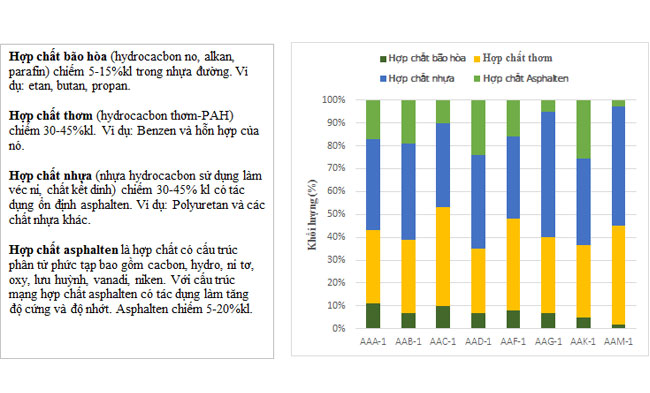

BITUMEN CHEMISTRY

S.A.R.A.

IT IS FUNDAMENTALLY INSUFFICIENT TO DEFINE THE QUALITY OF A BITUMEN BY ITS PHYSICAL PROPERTIES ONLY. THAT IS BY ITS NORMALLY DEFINED PROPERTIES OF PENETRATION, VISCOSITY, SOFTENING POINT ETC.

Known for its adhesive and cohesive assets, bitumen is mostly utilised in the construction industry. Bitumen is applied on road paving because it is viscous when hot, but solid once it cools down. Therefore Bitumen operates as the binder/glue for pieces of the aggregate.

Bitumen is applied in construction and maintenance of:

- Highways

- Airport runways

- Footways / Pedestrian Ways

- Car parks

- Racetracks

- Tennis courts

- Roofing

- Damp proofing

- Dams

- Reservoir and pool linings

- Soundproofing

- Pipe coatings

- Cable Coatings

- Paints

- Building Water Proofing

- Tile underlying waterproofing

- Newspaper Ink Production

- And many other applications

In order realize the complexity of bitumen as a product an in-depth knowledge and detailed understanding for one of the way the roads are built is crucial. Specialists in bitumen know bitumen as an advanced and complex construction material, not as a mere by-product of the oil refining process. The ultimate paving material (also referred to hot mix asphalt concrete – HMAC or HMA) consists of about 93 – 97% mineral aggregate (stone), sand and filler. The remaining percentage is bitumen.

How is bitumen Produced?

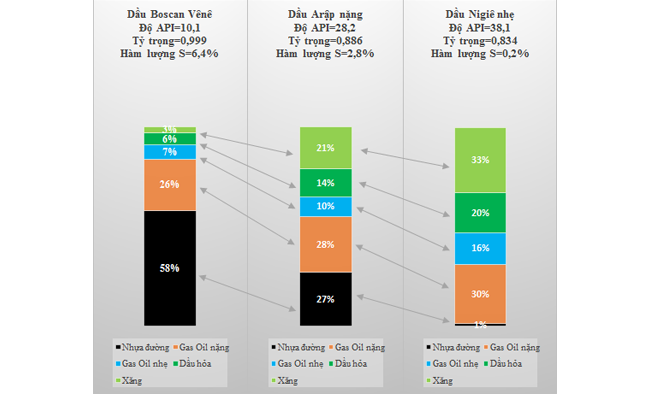

Petroleum Bitumen, normally called “Bitumen” or “Asphalt” is produced by refining crude oil. Used as a binder in road-building products, it is a very viscous, black or dark brown material.

The crude oil is pumped from storage tanks, where it is kept at about 60°C, through a heat exchanger system where its temperature is increased to typically 200°C by exchanging heat gained from the cooling of newly produced products in the refining process. The crude is then further heated in a furnace to typically 300° C where it is partly vaporized into an Atmospheric Distillation Column. Here the physical separation of the components occurs. The lighter components rise to the top and the heaviest components (the atmospheric residue) fall to the bottom of the column and pass through a second heat exchanger prior to treatment in a vacuum distillation column. Finally, Bitumen is obtained by vacuum distillation or vacuum flashing of atmospheric residue from the vacuum distillation column. This is "straight run bitumen”. This process is called bitumen production by straight run vacuum distillation.

An alternative method of bitumen production is by precipitation from residual fractions by propane or butane-solvent deasphalting. The bitumen thus obtained has properties which derive from the type of crude oil processed and from the mode of operation in the vacuum unit or in the solvent deasphalting unit. The grade of the bitumen depends on the amount of volatile material that remains in the product: the smaller the amount of volatiles, the harder the residual bitumen.

Specialists in bitumen view bitumen as an advanced and complex construction material, not as a mere by-product of the oil refining process.

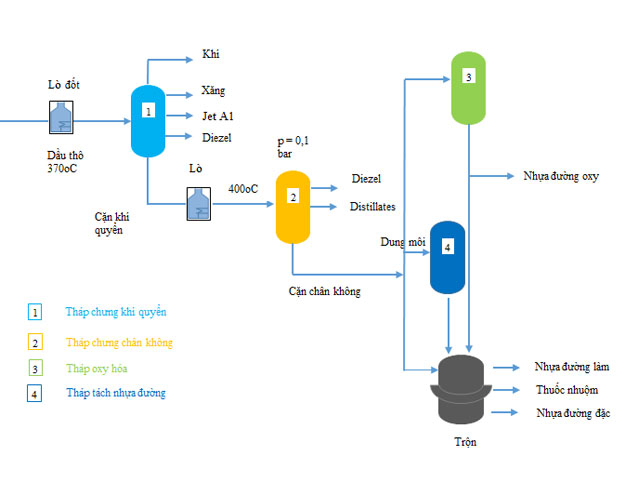

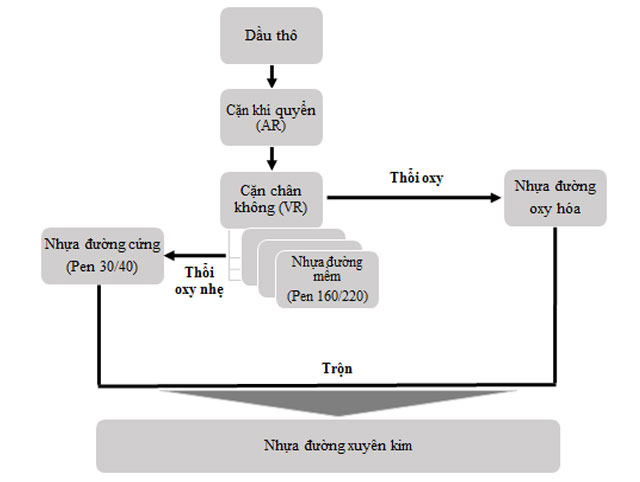

Standard Bitumen Production Scheme

Typical Bitumen Production Scheme

Bitumen Standards & Grades

Standardizing Bodies

In different regions and countries, different Standards and Grading systems are used for determining the quality of petroleum bituminous Binders. The most recognized standards for petroleum bitumen are published by

-

European Committee for Standardization (CEN)

- Deutsche Industrie Norm (DIN EN)

- Association Française de Normalisation (AFNOR – NF EN)

- BSI Standards - the UK's National Standards Body (NSB - BS EN)

- American Society for Testing and Materials (ASTM)

- American Association of State Highway and Transportation Officials (AASHTO)

- South African Standard Organization (SABS)

- Standards Australia (AS)

Most Commonly Used Bitumen Specifications

STANDARD PETROLEUM BITUMEN GRADES

- ASTM D 946 and AASHTO M 20 (Penetration @ 25°C)

- ASTM D 3381 and AASHTO M 226 (Viscosity @ 60°C)

- ASTM D 6373 and AASHTO M 320 (PG-Graded Binder)

- EN 12591 (Penetration @ 25°C) → NF EN; BS EN; DIN EN; etc.

- AS 2008 (Viscosity @ 60°C)

- SABS 307 (Penetration @ 25°C; Viscosity @ 60°C after RTFOT)

- IS 73 (India) changed in 2006 from PEN grades to VG Grades (based on Viscosity @ 60°C); however, CRMB modified bitumen is still graded based on penetration.

POLYMER MODIFIED BITUMEN

- ASTM D 5976; ASTM D 5840; ASTM D 5841 (based on polymer type; now outdated and not used in the USA, but still used in some developing countries)

- ASTM 6373 and AASHTO M 320 (PG-Graded Binder; applicable to Unmodified and Polymer Modified Bitumen)

- EN 14023 (Framework Standard for Polymer Modified Binder)

- AUSTROADS Framework Specifications (Australia)

BITUMEN EMULSIONS (ANIONIC; CATIONIC; UNMODIFIED; POLYMER MODIFIED)

- USA Anionic Emulsions: ASTM D 977 and AASHTO M 140

- USA Cationic Emulsions: ASTM D 2397 and AASHTO M 208; Polymer Modified Cationic Emulsion: AASHTO M 316

- Europe: Harmonized Framework Standard EN 13808 for Cationic Unmodified and Polymer Modified Emulsions; many different national

- Annexes. (Note: Internationally there exist a very broad range of emulsion specifications; many of them are technically inaccurate and confusing.)

CUTBACK BITUMEN

- ASTM D 2026, D 2027 and D 2028 for Slow, Medium and Rapid Curing Cutback

- AASHTO M 81, M 82 for Rapid and Medium Curing Cutback

- EN 15522 Cutback and Fluxed Bituminous Binder