Refinery

IntroVung Ro Petroleum has been developing onshore Refinery and Petrochemical Complex in Vietnam. The project is located in the Phu Yen Economic Zone.

Implementation of the full-fledged refinery project has been suspended since 2015, though the project had successfully passed the basic engineering design and FEED stages.

After thorough and comprehensive discussions regarding the optimization of the refinery configuration, it was decided to breakdown the project implementation into several phases.

Phase 1a: Bitumen Terminal Facilities

Phase 1b: Heavy Crude Oil Refinery Complex of 2 MTPA on feedstock

Phase 2: Naphata Complex and Heavy Residue Desulphurization (Hydrotreating)

Phase 3: Refinery Complex Expansion up to total capacity of 8 MTPA on feedstock

Phase 1a

The first phase of the Project is Bitumen Terminal facilities that include the following:

1. 2×5000 TONS BULK TERMINAL

Bulk Bitumen Storage Terminal of 2×5000 MT capacity, capable of receiving 5000 DWT bulk ocean vessels. The marine infrastructure includes the bitumen intake facilities, transferring pipelines for bitumen offloading.

2. POLYMER MODIFIED BITUMEN PRODUCTION

Storage terminal blending facilities, capable of production of stable Polymer Modified Bitumen, Superpave® spec bitumen under AASHTO and ASTM.

3. BITUMEN EMULSION PRODUCTION

Bitumen Emulsions production for Tack Coating, Prime Coating, Micro-Surfacing, Chip Sealing and Pot Hole Patching applications.

The bitumen (the plant feedstock or polymer modified products) may be distributed directly by special trucks (heated bitumen trucks) or by ordinary lorry trucks (when bitumen packed in big-bags or barrels);

Phase 1b

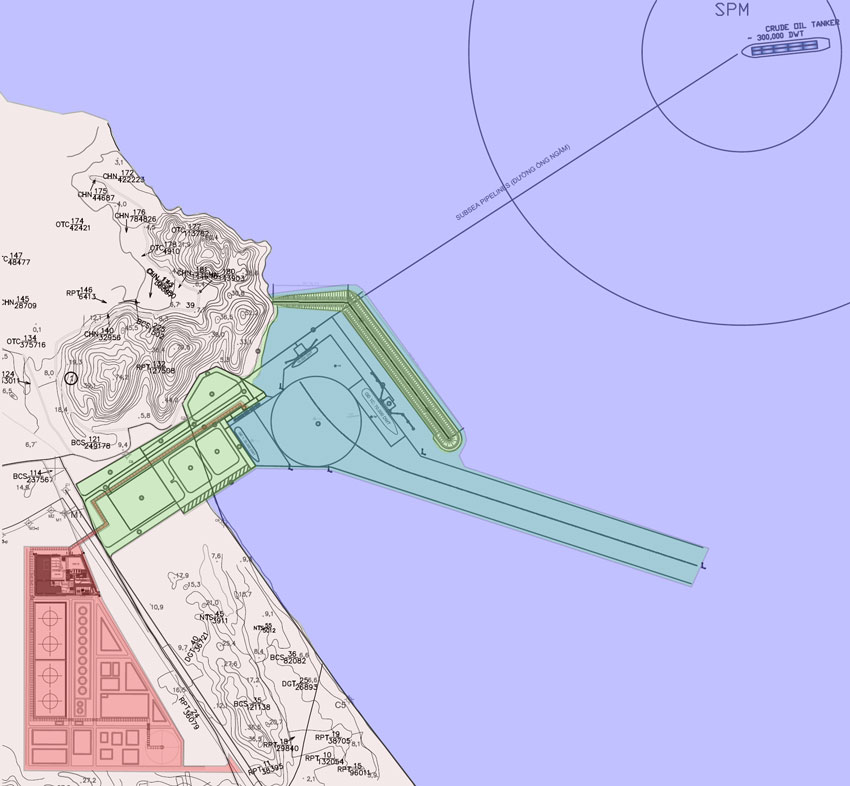

Phase 1b of the Project targets to implement 2 MTPA Refinery (including crude oil intake marine facilities - SPM) on the project site.

The process solutions include crude oil distillation column, vacuum tower and oxidizer as main refinery units. The product slate include straight-run products: MGO, MDO, bitumen and naphtha.

The project features the following facilities:

1. Double service (crude oil/diesel) storage and transshipment tank farm of 4×50,000m3 capacity;

2. Single Point Mooring (SPM) facilities for crude oil intake;

3. Export Liquid Bulk Jetty capable of receiving the vessels of up to 50,000 DWT and secured by a breakwater structure;

4. General Cargo Terminal for the needs of the Refinery and Province;

Phase 2 and 3

The scope of the Phase 2 of the Project assumes the expansion of the process configuration within a number of advanced process technologies, including Naphtha Processing Complex and Heavy Residue desulphurization units. The second phase assumes substantial marine facilities development including additional liquid bulk jetties and general cargo terminals.

The process configuration development and implementation is highly flexible and will be finalized on later on.

This phase of the production facilities development will enrich the refined product slate with more environmentally friendly products including low sulfur gasoline (Euro 5), diesel (Euro 5) and low sulfur marine fuels (in accordance with IMO 2020 environmental regulations).

The scope of the Phase 3 of the Project assumes the expansion of the process configuration within a number of advanced process technologies, so the total capacity of the Refinery Complex Capacity will reach 8 MTPA on the feedstock throughput. The third phase of the expansion of the marine facilities features the provincial cargo terminal, which is located adjacent to the refinery cargo terminals (on south).

The expansion of the refinery process facilities may include Naphtha Processing Complex including such processes as Naphtha Hydrotreating, Reforming with Continuous Catalyst Regeneration (CCR) and Isomerisation (PENEX), as well as RFCC (Residue Fluid Catalytic Cracking) and HRDS (Residue Hydrodesulphurization) complexes.

The process configuration development and implementation is highly flexible and will be finalized on later on.

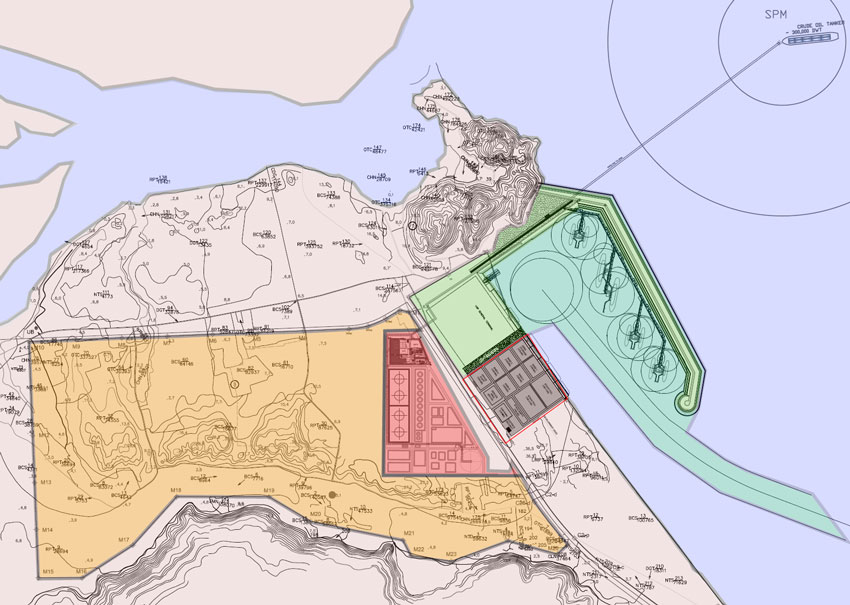

Phase 3 expansion area showed in orange.